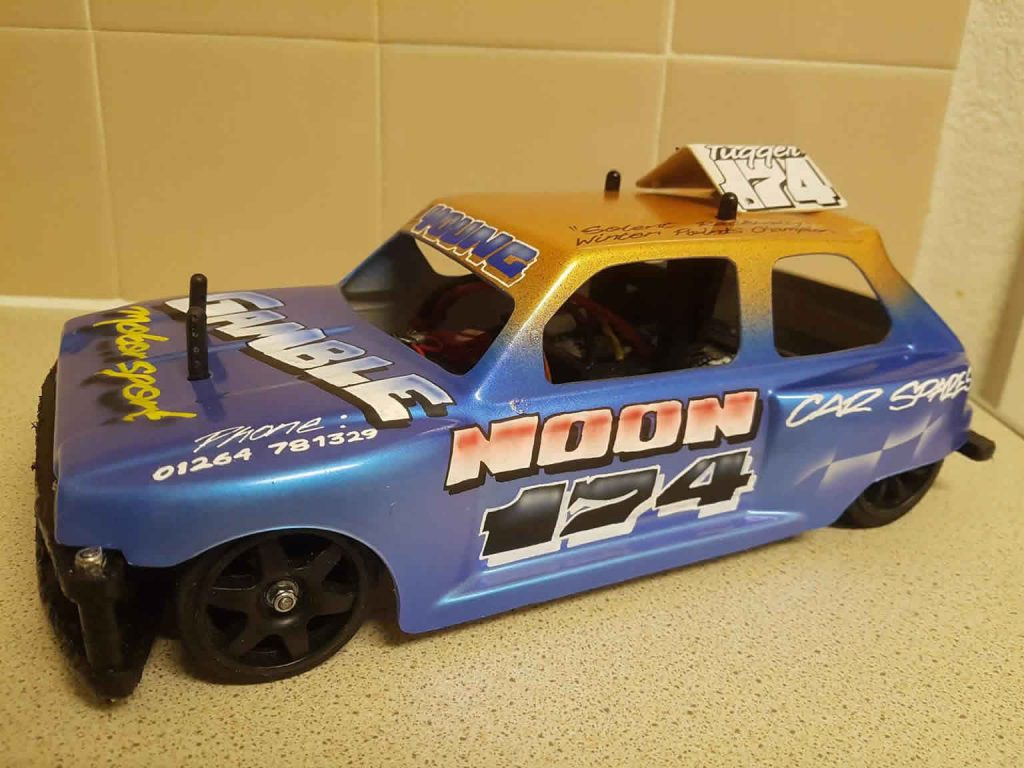

1300 Stox

For beginners with little experience we suggest you start with 1300 Stox.

These are the most forgiving formula and easiest to drive but are also competitive.

Contact is allowed in this class so crashing is common but with the big bumpers damage is kept to a minimum.

If you require any further information please contact us.

1300 Stock Car Construction Rules 2024

1) Body to be ABS and a reasonable representation of a full size 1300/1400 stockcar. Spoilers are not permitted. Shells to be of a ‘hot hatch’/ ‘cc’ style no estates or saloon styled shells. Windows Must be fully cut out.

2) The chassis component will consist of one continuous sheet of aluminium or glass fibre-reinforced plastic only. Minimum thickness of 2mm Chassis must extend from a minimum 10mm ahead of the front axle line and run continuously along the car to end a minimum of 25mm behind the rear axle line. Winged style chassis is permitted.

3) Mardave/Kamtec type rear pod base plate, pivot ball and standard V12 spring location, or equivalent parts in shape and construction and mounting locations. 2 rear springs only.

3a) standard Mardave/Kamtec A-arm style front wishbones Only. To be made of plastic only no alloy. NO zen, Schumacher, Rsgt, Rxgt, Atom, Venom style parts are to be used. (GT12 parts not eligible).

4) External plastic bumpers to be fitted to the chassis front and rear. Front to be grid and representative of a full-size stock car. Min height of 25mm and max height of 35mm from chassis to top of the bumper. If a single rail rear bumper is used, it may be spaced up from the chassis. Spacers to be a max length of 8mm. If a grid bumper is used on the rear, it must follow all rules of the front bumper. Fixings are not included in height measurements.

5) Overall maximum width of the rolling chassis to be 161mm bumpers may exceed this by 3mm to allow for impact damage and distortion (178mm including body and

bumpers).

5a) Wheelbase of 205mm +/-5mm only.

6) Materials used in the rolling chassis may only be steel, brass or aluminium. Special materials (such as titanium or carbon) are not allowed. Brass and lead only may be used as identifiable weights.

6a) chassis must not have any extra holes drilled or added to allow extra ‘flex’ in the chassis component and that the chassis must be a solid design not slotted to achieve extra Movement. 75% of the chassis by area to remain uncut.

7) Damper tubes are not allowed. Oil filled shocks and dampers are not allowed.

8) Front suspension may be independent provided that the suspension design does not have any pivot, rod or other mechanism that alters the wheel camber or castor in roll relative to the chassis during its full travel. and must use the standard two bolt fixing, and not modified/elongated.

8b) Ride height/castor can be adjusted with shims/washers. Shims and washers must be made from a solid substance to be a consistent thickness start to finish and rigid.

9) Rolling element (ball) bearings are allowed on the front and rear axles.

10) Min 25mm, max 26mm width of tires, wheels must be of standard offset, wheels must be fitted the correct way round as intended. Max 60mm diameter no Min diameter of tyres, but the tyre must cover the entire wheel edge to edge. Tyre additives are NOT allowed.

11) Diffs are not permitted.

12) Gearing is limited to a 32dp pitch for pinion and Spur gear.

13) Z drives and alloy pods are permitted. height adjustable rear pods are not permitted.

14) Any 12th scale single bolt wheel to be used, mounted onto a steel axle only.

15) Powered by 4cell brushed setup. cell layout is free and open for driver’s choice. Motors 540 Silvercan 20 turn limit such as Core 21, Kamtec K21, Mardave G2.

15a) Speed controller maximum RRP of £60 BUT it must be commercially available. Electronic speed controller or mechanical resistor type speedo controller permitted.

16)minimum ride height 3mm including bodyshell, 1mm spur.

17) No GT12 hybrid style cars to be used.

18) Additional holes may be drilled for the re-mounting of the body post and aerial mast locations only.

19) parts from other manufacturers may be used as long as they serve the same purpose.

20) All added weight must securely fixed or fitted under battery, care must be taken so cannot short out on the battery so we suggest covering any weight to insulate it.